Week 11 is done, today we begin a new week, new assignmets and new challenges. For week 12 that has just started and is going to be about Molding and casting. During this week we need to use some machines, some materials and of course a good attitude for what is coming. So now join me in this new week journey and see what comes along, always hoping for the best. Basically the idea is to design a mold, machine it and cast it. This are the assignments I have to complete:

This week assignmets are:

Group assignments:

Individual assignments:

| Equipment | Materials |

|---|---|

|

|

ShopBot CNC

A CNC (computer numeric control) tool is used in prototyping and full production for cutting, carving, machining and milling in a variety of materials including wood, mdf, plastics, foams and aluminum. ShopBot Tools, like all CNC tools, move a cutter around a big table (X and Y axes) and move it up and down as well (Z axis) allowing it to make 3D movements and cut all sorts of shapes. The cutter looks like a drill bit and is spun by a motor called a router or spindle.

It can create virtually any pattern or shape and will do it in materials such as wood, plastic, foam, aluminum and many composites. You use the included software to design your parts on your personal computer, then, like a robot, the computer controls the cutter to precisely cut your parts. Now, all the types of computer-driven tools that create things by cutting material away (such as CNCs or laser cutters) or building up material in layers to create an object (3D printing) are called digital fabrication tools.

Unlike a drill bit, a router bit is designed to cut from the sides as well as the tip. By precisely moving the cutter through material, it can create virtually any pattern or shape and will do it in materials such as wood, plastic, foam, aluminum and many composites.

Data from: ShopBot CNC

3D printer

3D printers use CAD to create 3D objects from a variety of materials, like molten plastic or powders. 3D printers can come in a variety of shapes and sizes ranging from equipment that can fit on a desk to large construction models used in the making of 3D-printed houses. There are three main types of 3D printers and each uses a slightly different method.

Data from: 3D printer

Is a process of making three dimensional objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Is a process in which a digital model is turned into a tangible, solid, three-dimensional object, usually by laying down many successive, thin layers of a material. 3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a block of material with for instance a milling machine.

Data from: 3D printing

To begin with the assignments it's important to know about the materials we are going to use. For the mold I decide to use yeast type III. Before we begin, we have to make sure about the sacurity and safety measures. So here it is what we have to know:

| Safety measures yeast | ||

A1). First Aid Measures |

A2). Working area |

A3). Personal protection |

Data from: First Aid Measures |

Data from: Personal safety |

Data from: Personal safety |

For my first casting example I'll try acrylic and as we did with yeast lets leearn important points regarding safety: :

| Acrylic safety measures | ||

B1). Acrylic first aid Measures: |

B2). Exposure control |

B3). Personal protection |

Data from: First Aid Measures |

Data from: Acrylic safety precautions |

Data from: Personal safety |

For a second casting example I will use Resin. So, as we did with yeast and acrylic lets see important points regarding safety:

| Epoxy Resin Part A | |

C1). Hazard Statements |

C2). Description of first aid measures |

|

Causes skin irritation May cause an allergic skin reaction. Causes serious eye irritation. Toxic to aquatic life with long lasting effects |

Inhalation: Move the exposed person to fresh air at once. Keep the affected person warm and at rest. Get prompt medical attention. Ingestion: Do not induce vomiting! Rinse mouth thoroughly. Promptly get affected person to drink large volumes of water to dilute the swallowed chemical. Get medical attention immediately! Skin contact: Rinse the skin immediately with lots of water. Get medical attention if any discomfort continues. Eye contact: Remove victim immediately from source of exposure. Make sure to remove any contact lenses from the eyes before rinsing. Promptly wash eyes with plenty of water while lifting the eye lids. Continue to rinse for at least 15 minutes and get medical attention. |

Data from: Resin safety Datasheet.

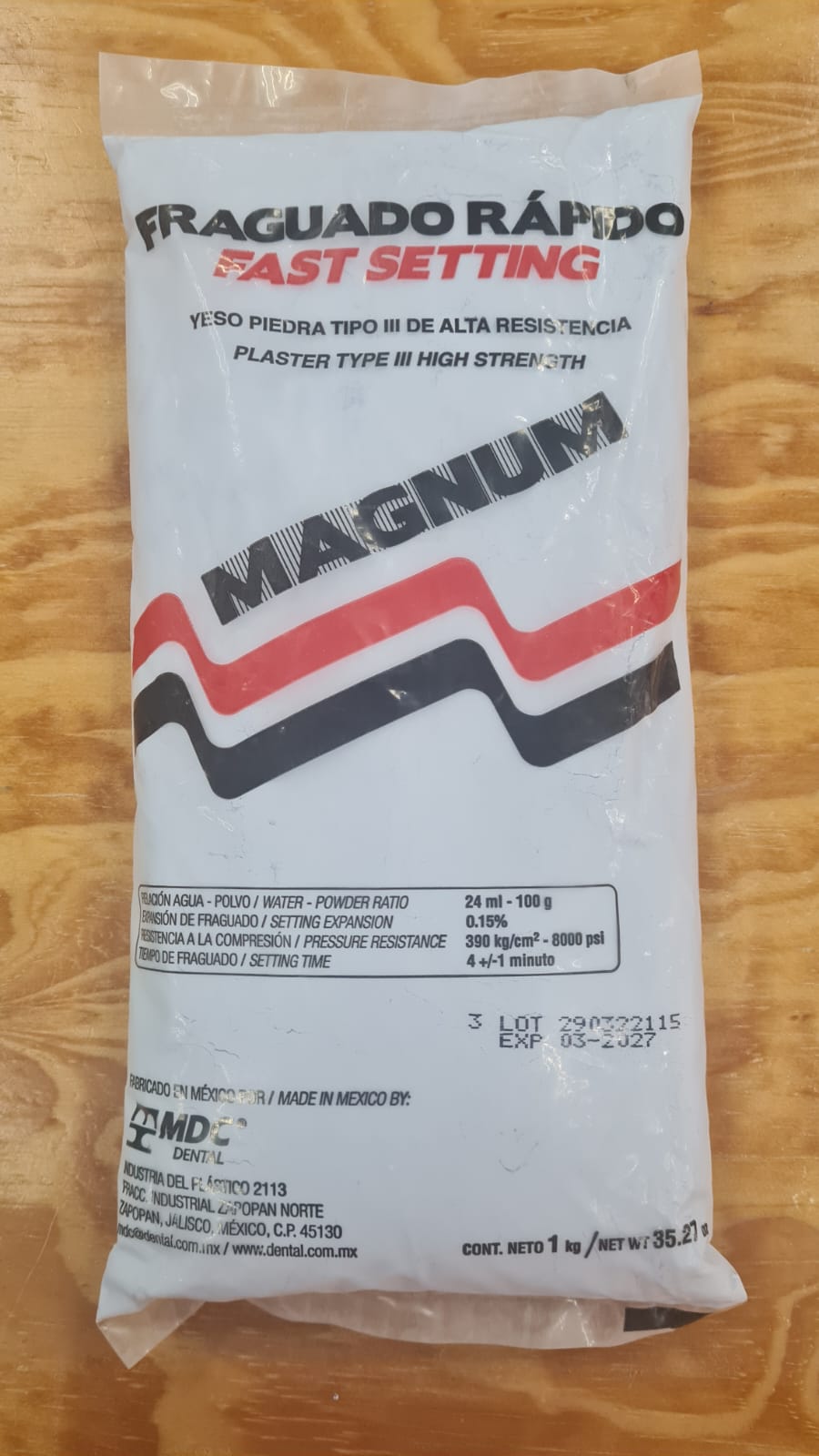

For this initial part i'm using yeast type III to make the mold. According to the instructions on the yeast bag it indicates to use water and the yeast. The mixture should be in the next proportions:

So, I prepare all the materias I was going to use and start my mold. Lets see the results I got from my test #1 mixture. In the next images yo can see that the mix work better that the first results that are shown in the P.I.C.N.I.C section.